Services

Data recovery from RAID

Data recovery from HDD / SSHD

Data recovery from SSD / NVMe

Data recovery from pendrive and memory card

Firmware database

Price list

Address and contact

There is no program for repairing physically damaged sectors - so-called bad sectors.

The longer we force the disk to work, i.e. read individual sectors, without knowing its technical condition, the more difficult subsequent data recovery may be.

This situation may occur when the reading and writing elements of the head have been damaged and the working head is unnecessarily loaded and is subject to further degradation, or the surface of the disk platters has been damaged and may be further damaged during scanning.

While in the first case the solution is to replace the heads from the donor disk, the damage to the surface of the platters is irreversible.

If the disk is still able to read data, you should immediately make a post-sector copyof the damaged drive to a healthy medium or file and recover data from it.

In the event of a failure of the hard disk electronics, simply replacing it in modern drives is ineffective.

This is due to the fact that currently produced hard drives have such a high data storage density that each of them has individual operating parameters assigned to them stored in ROM.

With just the gear ratio, the disk is not able to calibrate itself properly to work.

As technology develops, new faults also occur, which are also confused with PCB damage and are located in the firmware, which occurs in the so-called Service Zone. This, in turn, is located on the magnetic surface of the disk and has nothing to do with external electronics.

In addition, manufacturers of magnetic media began to increasingly secure their products by blocking service access and hardware encryption of user content.

The fault is often confused with electronics damage. However, in most cases it concerns damage to the head assembly.

During operation, the head floats on an air cushion and the distance between the writing and reading element and the magnetic surface is approximately 1 micrometer. The reason for this phenomenon is the high rotational speed of the discs and the flexible arms of the head

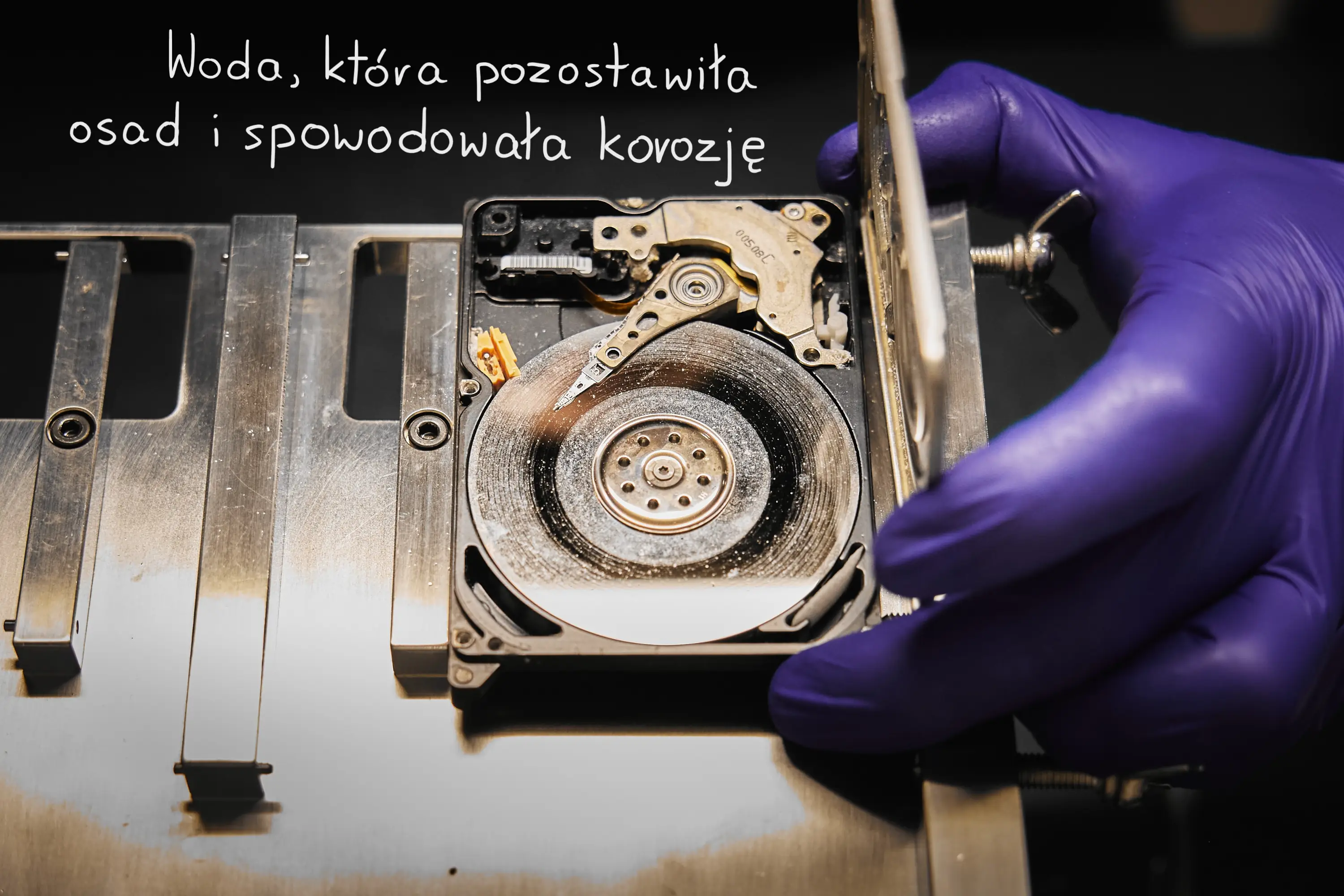

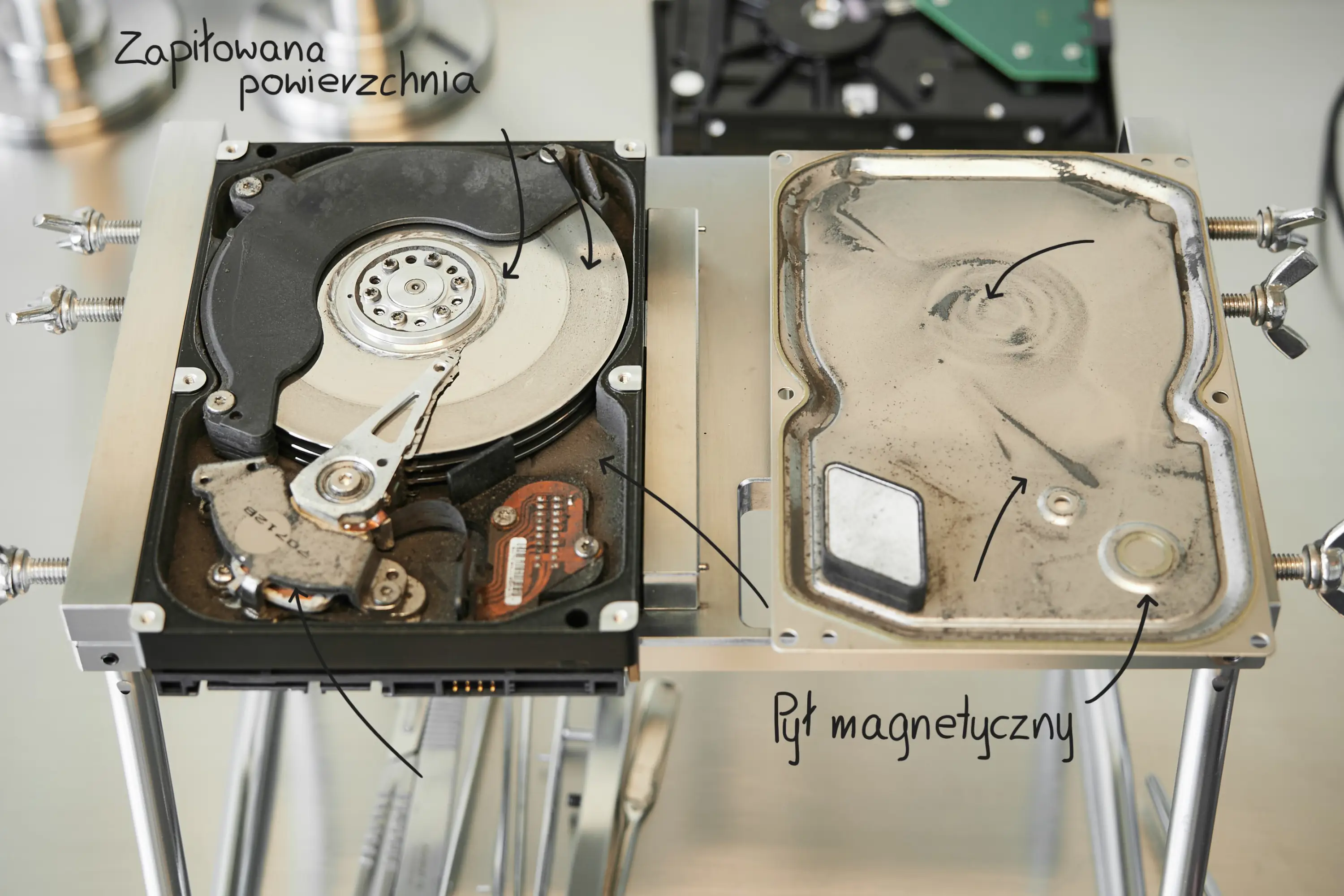

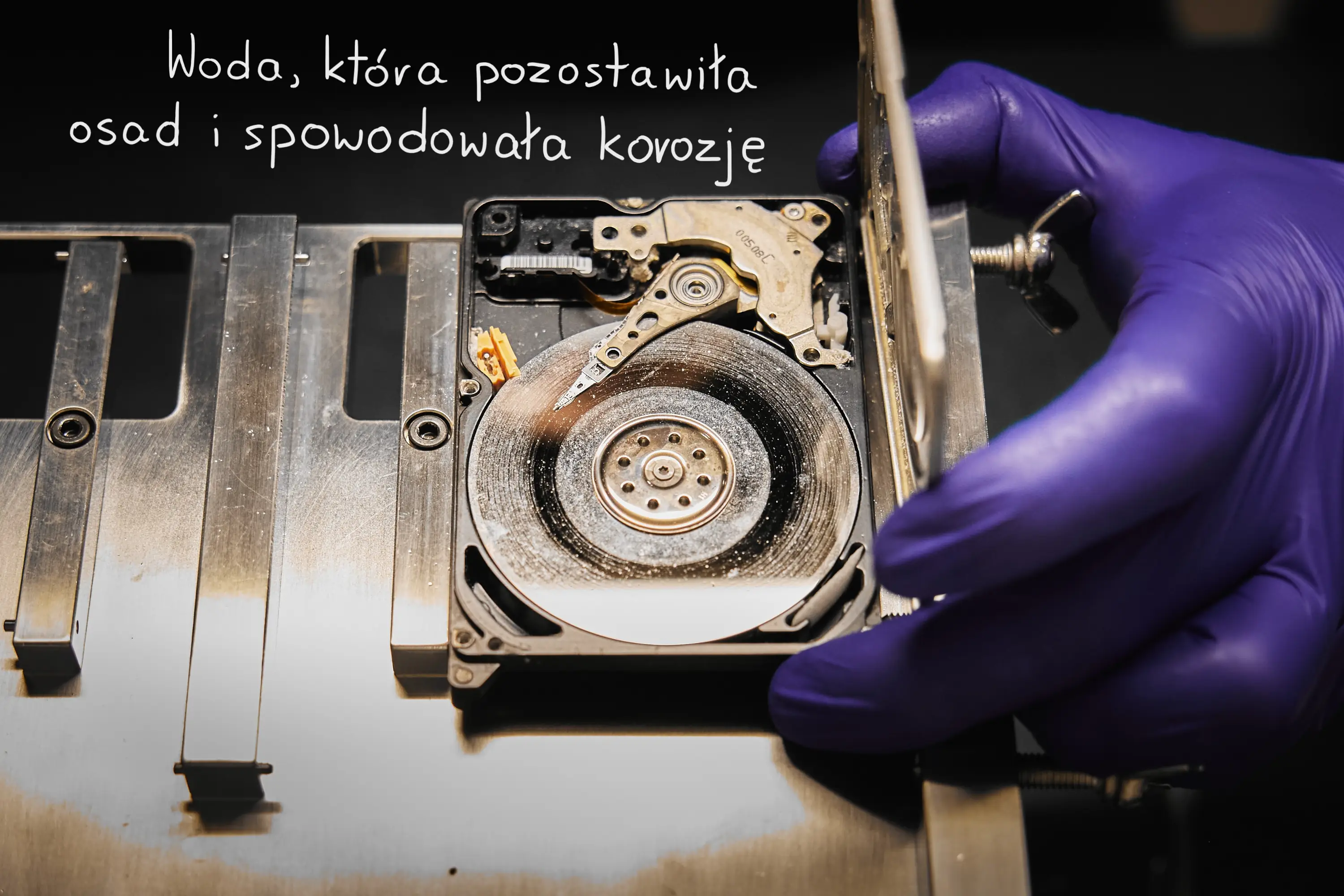

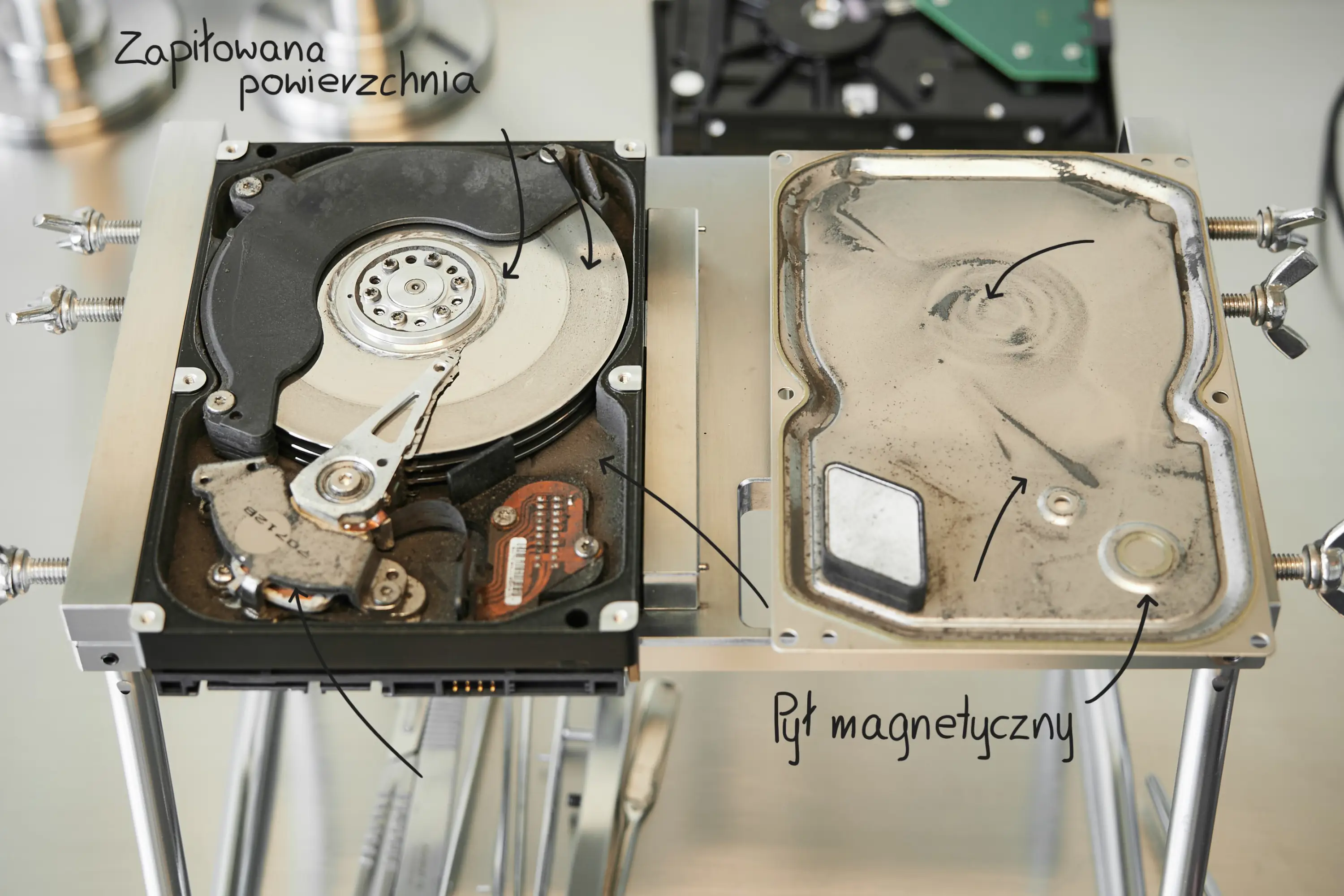

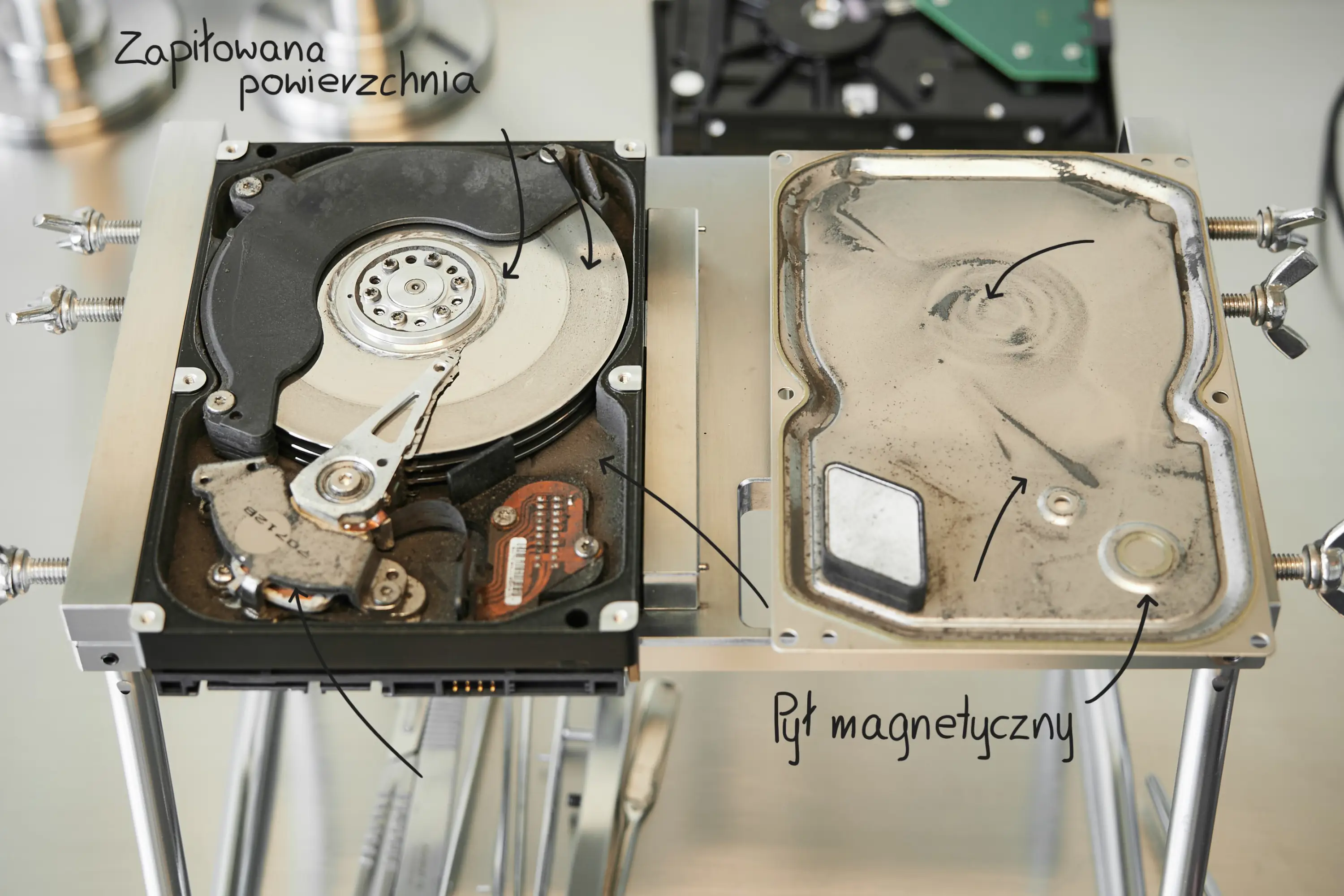

Head failure may result from a power outage or from any shocks during operation. In such a case, the reading and writing elements may become detached and contribute to sawing of the plating surface.

The second frequently encountered defect related to shock or fall of the disk is the sticking of the reading and writing elements of the heads to the surface of the platters.

In such a situation, the disk will not be able to start the drive axle, and disturbing sounds will come from the disk - for example, a quiet squealing at intervals of about half a second to one second.

It is best not to run drives after such events or with similar symptoms.

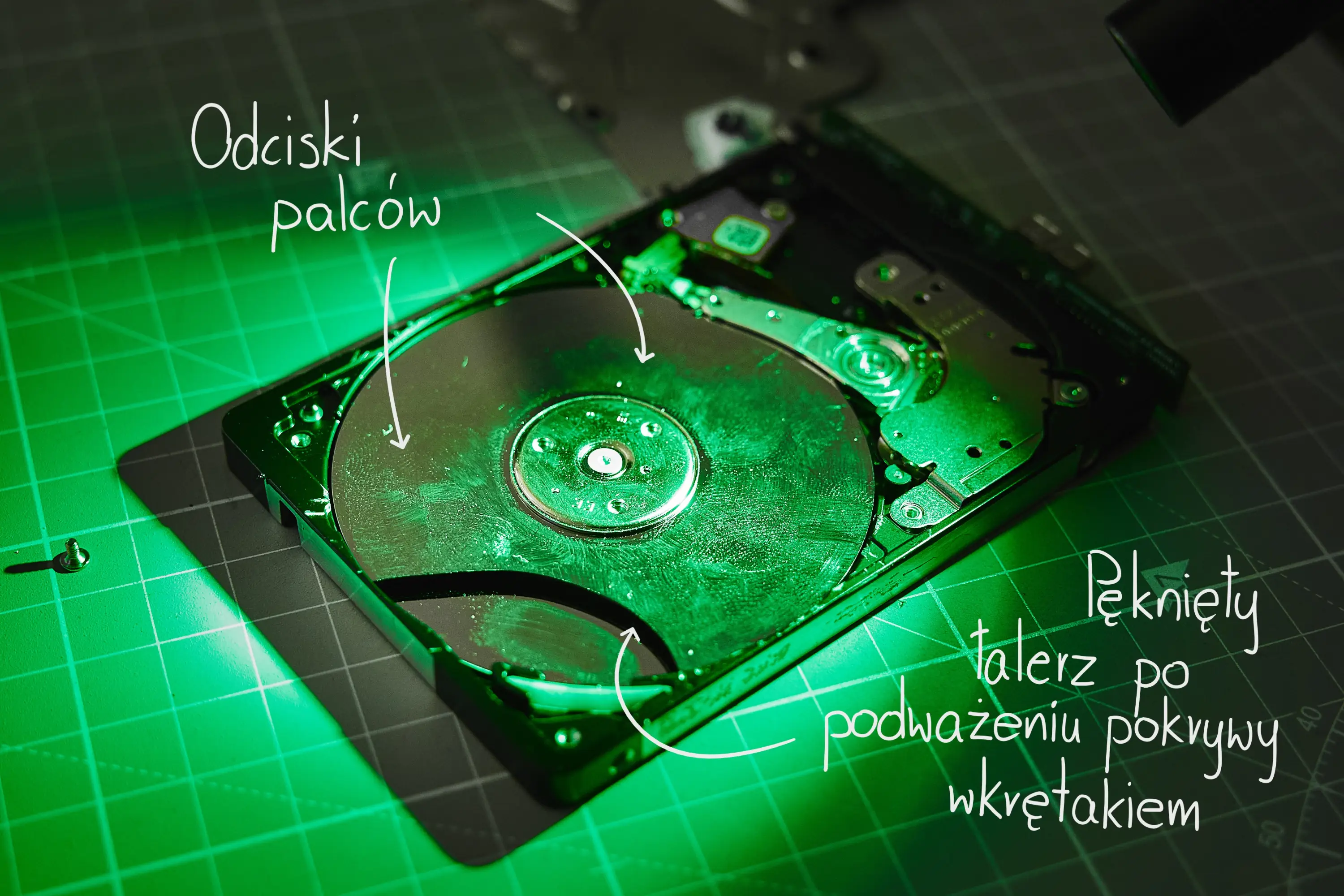

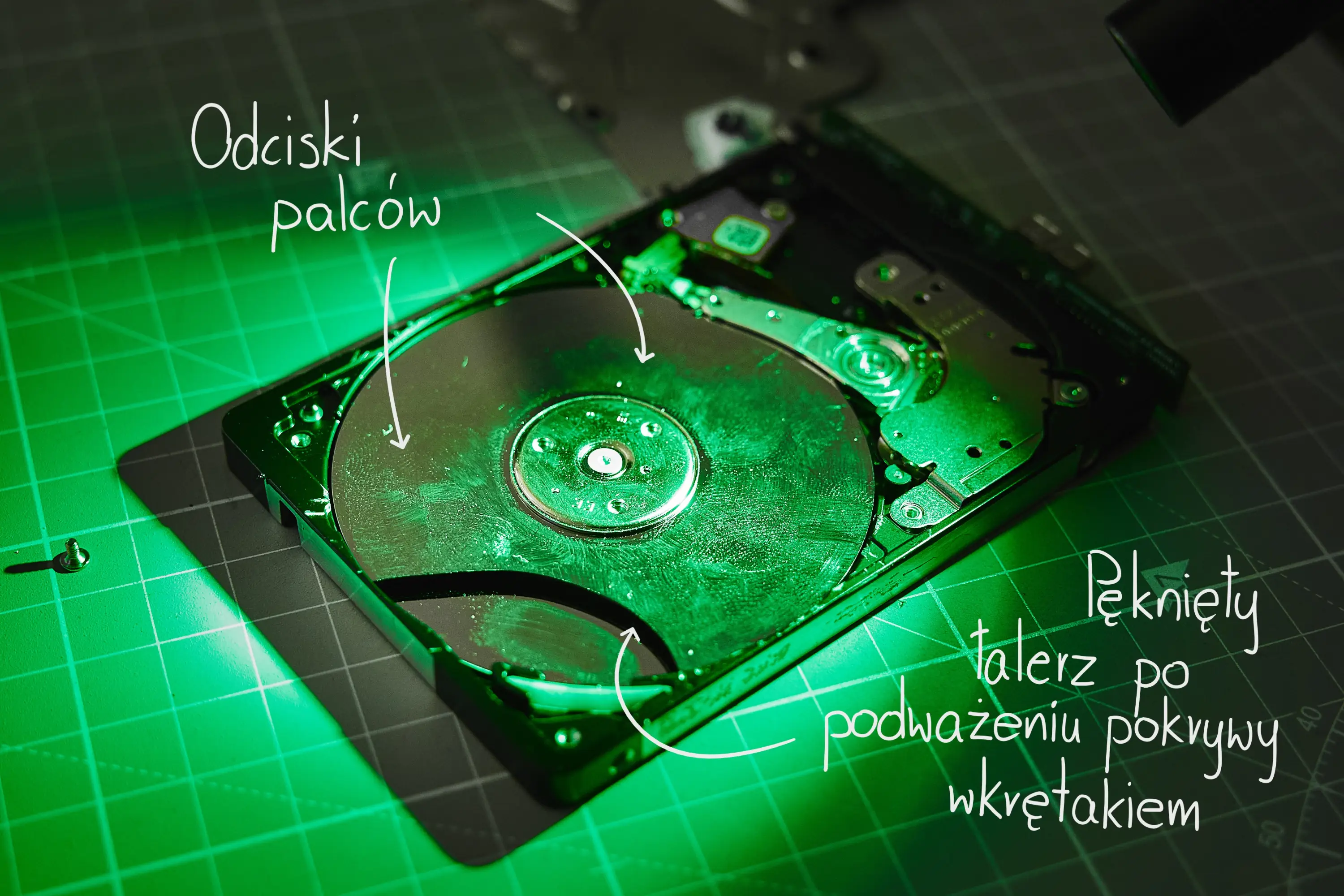

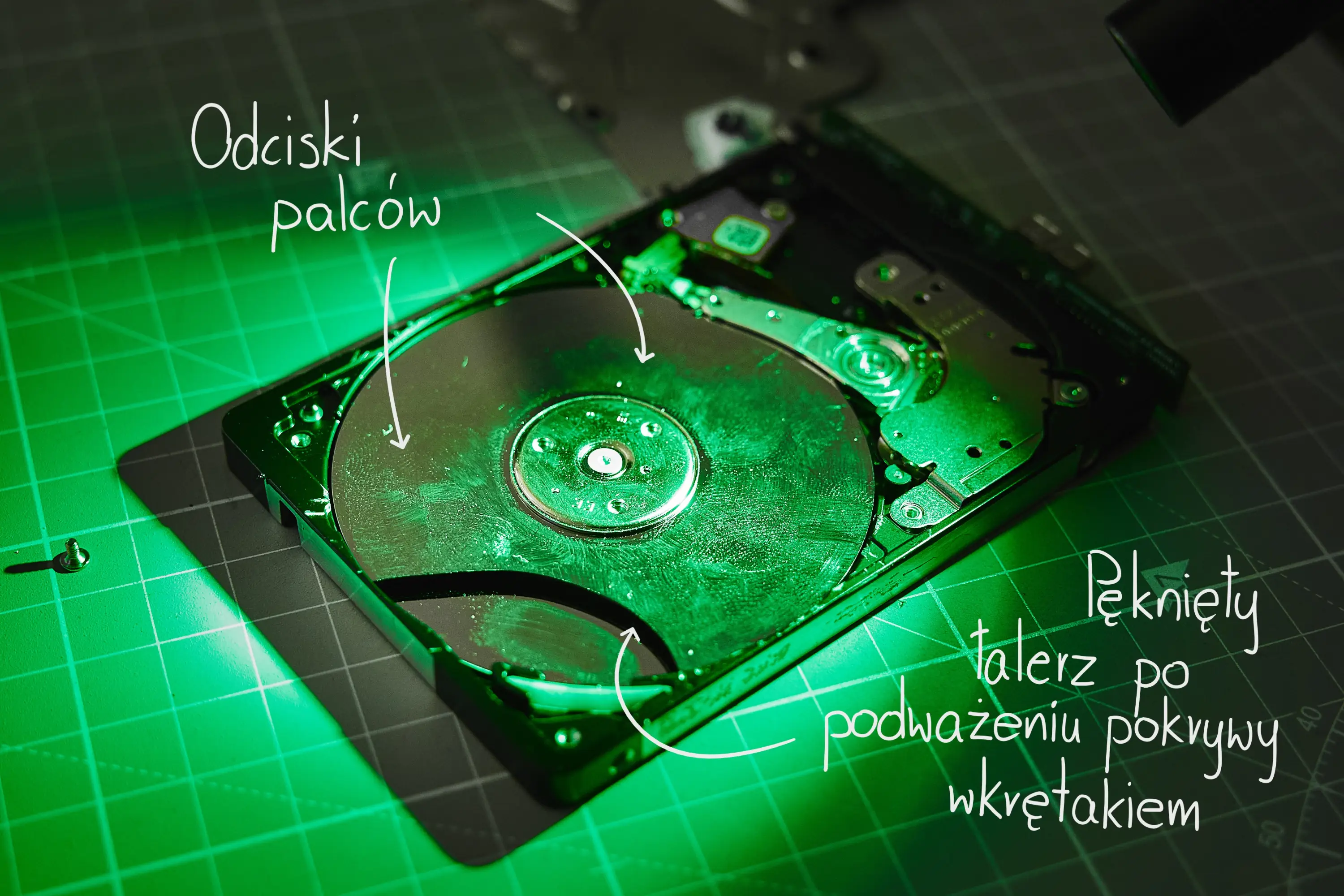

Opening the disk in unfavorable conditions, i.e. outside the laminar chamber, is a common mistake.

And this is not about the false claim that there is a vacuum inside a traditional disk or that there is a special gas inside them.

Hard drives contain high-purity air, and the drives themselves are equipped with ventilation holes and filters to equalize the pressure and allow the formation of an air cushion.

Opening the cover in such conditions ends up dirtying the platters, and you should remember about the previously mentioned data recording density - a dust particle that may be invisible to the naked eye may hit the head during the rotation of the platters and damage it or scratch the surface of the plates and damage most of the sectors.

Data recovery after such home procedures is very difficult or sometimes even impossible.

Returning for a moment to the information that hard drives contain gas - yes, helium-filled drives, the so-called Helium Hard Drive, have recently been produced and available for sale. They have two covers, the top one of which is integrated with the carrier body and is non-removable.

This is an action that is performed as a last resort.

There are two situations when it is necessary to dismantle the plates.

The first is a situation in which the correct rotation of the motor is impossible due to damage to the bearing, winding or bending of its axis.

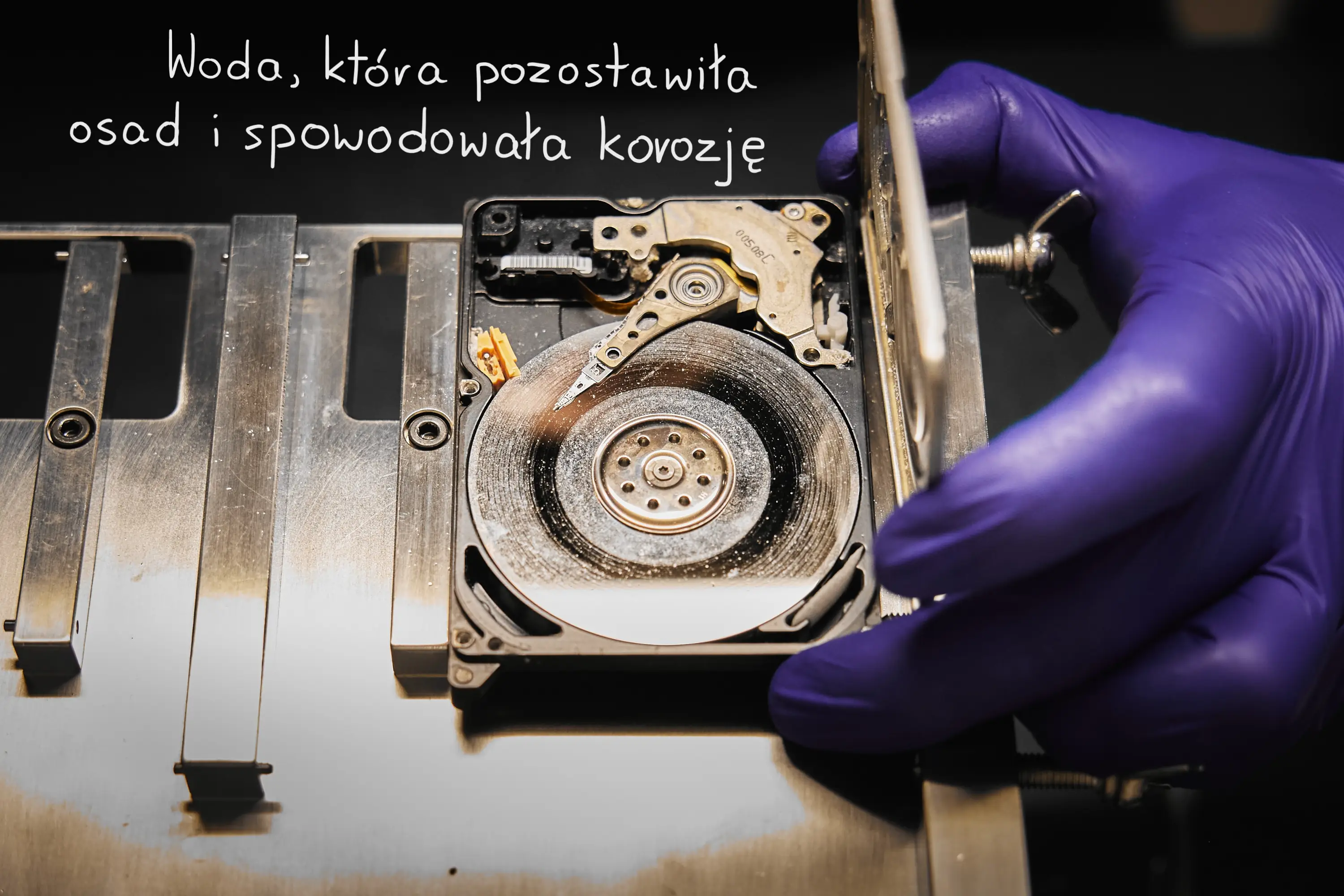

The second situation is the need to inspect the surface and possibly remove dirt.

Until recently, it was believed that desynchronization of the platters made any recovery procedures impossible.

Some disks are indeed very sensitive to changes in the position of the plates relative to each other, but we managed to develop a method for marking their position and programmatic control of the read area.

Thanks to these procedures, it is possible to recover data from disks that have a damaged magnetic surface, are dirty with sawing dust, or whose contamination comes from external conditions and is located on the bottom surfaces of the plates.